Building designs are progressively becoming more abstract and relying on creative structural solutions to support these visions. Technology, expertise and adaptability are all key drivers, but what actually carries these solutions to success?

The relationship between a Structural Engineer and a construction team is one of the most important alliances within the project development mix. The two collectively play the role of legitimising the architectural intent of a project and setting parameters on the physical feasible to form outcomes that appease all stakeholders.

There is a common misconception that Structural Engineers are seen as ‘killjoys’ who minimise complex designs due to a myriad of different building constraints. At Matter, we aim to swipe this stereotype because creative design should never be bound by close-minded structural engineering. Instead, it should be complemented by building solutions that steer elegant designs. As the precursor to critical and permanent construction decisions, we base our solutions on this philosophy whilst continually upholding our duty to promote safety and functionality above all else.

So, how do we balance safety and creative intent? In our experience, a successful and efficient project is the by-product of a like-minded partnership, particularly with builders that match our vision and prioritise cost-effective and sustainable building solutions.

Case Study: Vibe Hotel, Adelaide

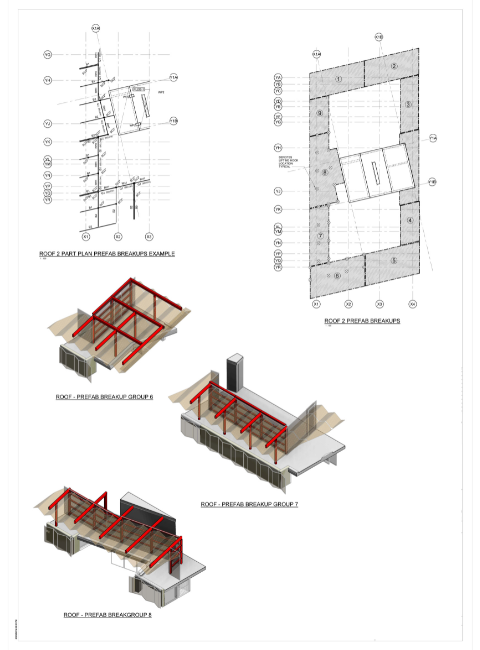

Matter recently worked alongside Synergy Construct to implement a prefabricated rooftop for The Vibe Hotel in Adelaide – a strikingly crafted architectural façade encompassing the interior of a hotel designed for luxurious stays. Loucas Zahos Architects came to us with an impressively designed rooftop canopy comprising 4-meter cantilevers that overhang the edge of the hotel building. Some 18 storeys above street level, it was our job alongside Synergy to tailor a build solution that could mitigate the risks involved with the project.

Optimising our in-house BIM team and working alongside experienced construction and architect partners, we put forward a prefab modular solution, one that could significantly reduce safety concerns and control material damage during the building and installation phases. Communication flow between all team members was paramount in order to shape a solution built on trust, expertise and communal input. The culmination of these processes meant that sign-off was swift and we could move onto navigating the transport and height risks involved with the installation. Breaking the canopy into 10 steel portals and cladding them pre-lift was a successful strategy appointed by Synergy Construct that improved the safety and speed of construction. In a total of 5 working hours the installation was complete with minimal on-site fixing, an efficient ending to a project that wasn’t limited by creativity or construction challenges.

Notes from senior team members at Matter and Synergy Construct

“Synergy Construct operate like a tier-one firm in every sense. As demonstrated by these roof modules, they strive to find the most practical solution for the design intent, with quality and safety as their unwavering foundation.” – Elliot Smith, Director and Co-Founder at Matter

“Matter shares our values of design and construction excellence. They see challenges as opportunities and always push to find the most appropriate solution. We welcome them to South Australia and look forward to continuing our relationship.” – Heath Price, Construction Manager at Synergy Construct

Strong building outcomes stem from strong building relationships and that’s why at Matter we work with like-minded companies that aren’t limited by creative design but rather inspired to develop actionable solutions. We strive to be leaders in this space and adopt strategies and technologies that bring functionality to some of Australia’s most complex building designs.

Prefabricated rooftop design and installation process:

- Prefab roof modules set up & coordinated in 3D with construction and architectural teams for feasibility and detailed design.

- Prefab modules sized and ready for practical transportation with on-site assembling and building capabilities.

- The modular frames were designed and built with inherent stiffness and strength to eliminate risk during the 18-floor ascend above flinders street.

- Modules were lowered into position and bolted by the construction team in short 15 minute on-site intervals.

- The Vibe Hotel in Adelaide with a fully installed prefabricated rooftop canopy.